Welcome To

One-Stop Cosmetic Packaging Manufacturer

About Daria

Leading Packaging Manufacturer

We offer a comprehensive range of products including nail polish glass bottles, essential oil glass bottles, plastic jars, plastic bottles, and cosmetics tubes, tailored to meet exacting standards and brand identities.

Why Choose Us?

Our optimized packaging solutions help reduce costs, enhance brand presentation, and improve overall product reliability.

6 Reasons Global Brands Trust Our Packaging Solutions

- ISO-Certified with Three-Tier QC System

- Full Customization: Logo to Surface Finish

- 72-Hour Stock Dispatch from 20,000 Sqm Warehouse

- Small Orders Welcome! MOQ from 1,000 pcs

- 5,000+ Precision Molds for Perfect Fit

- Free Pre-Production Samples Offered

Custom Packaging Solutions for Nail, Skincare, and Fragrance Brand

At Daria Packaging, we craft tailored bottles, jars, and tubes for your brand—customize with premium finishes (electroplating, rubber coatings) or create a unique mold. Enjoy fast prototyping, low minimum orders, and flawless quality, trusted by global beauty brands. Let’s bring your vision to life.

About us

Facility Scale

Covers 368 acres (approximately 24.5 hectares) with a built-up area of 100,000m² and warehouse space of 40,000m², ensuring efficient logistics and storage.

Glass Wordshop

- 9 Industrial Glass Furnaces

- 5,000+ Precision Molds

- 2,000 Skilled Workers

- Annual Output: 150,000 Tons

Plastic Workshop

- 8 Blow Molding Machines

- 20 Injection Molding Machines

- 6 Flexible Assembly Lines

- Annual Capacity: 50M Units

Precision Bottle Customization

Key Steps in Our QC Process:

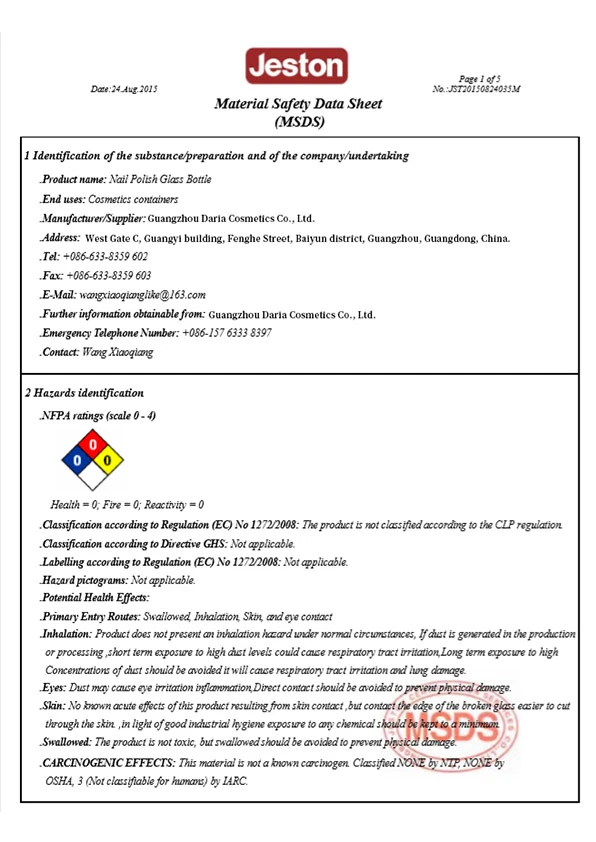

1️⃣ Material Safety

・FDA & REACH-certified materials for cosmetic use

・Leak-proof, thickness & clarity checks conducted per batch

2️⃣ Precision Production

・Auto + manual inspections at key production stages

・±0.1mm size accuracy for consistent fitting

3️⃣ Quality Guarantee

・100% defect testing before shipment

・ISO 22716 compliant quality management system

Quality Control

We craft glass bottles, plastic jars, and dropper bottles that meet the highest safety, durability, and aesthetic standards for skincare, nail art, and perfume brands.

Quality Assurance

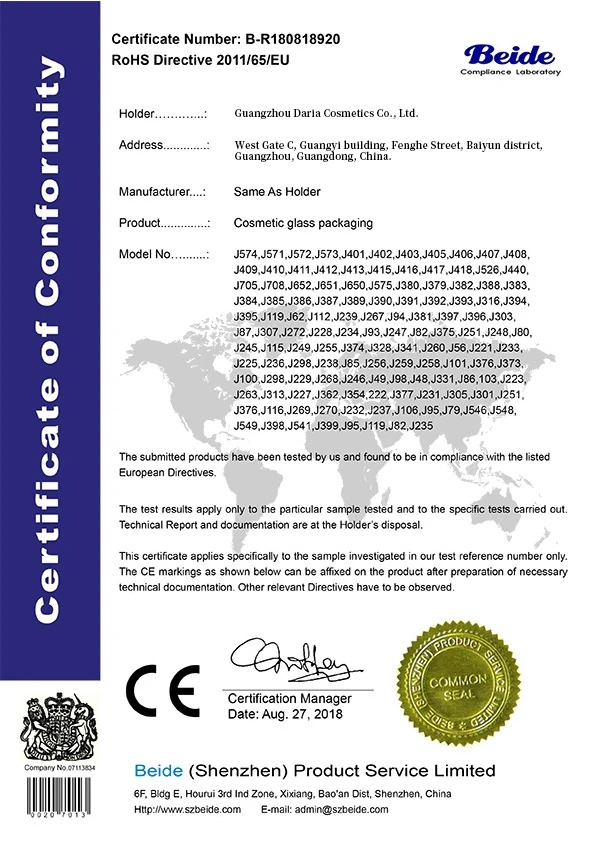

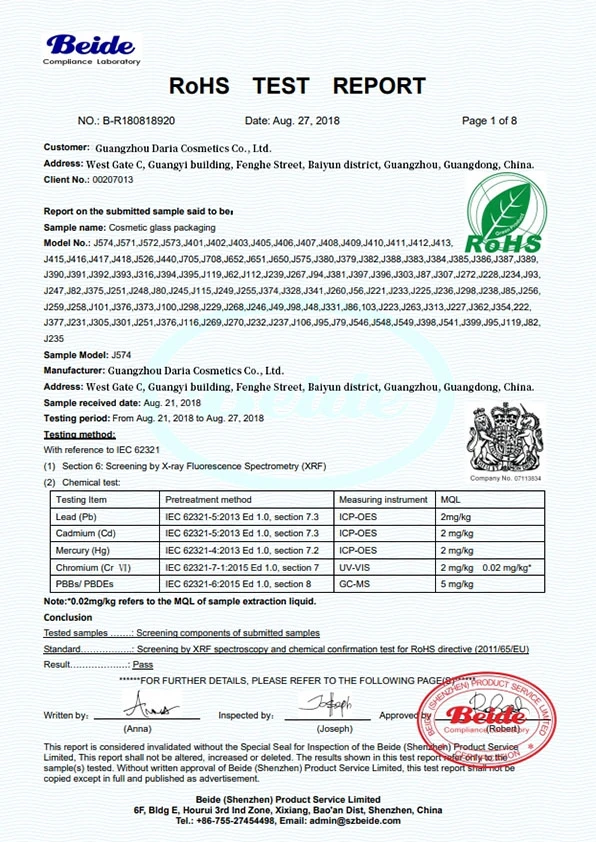

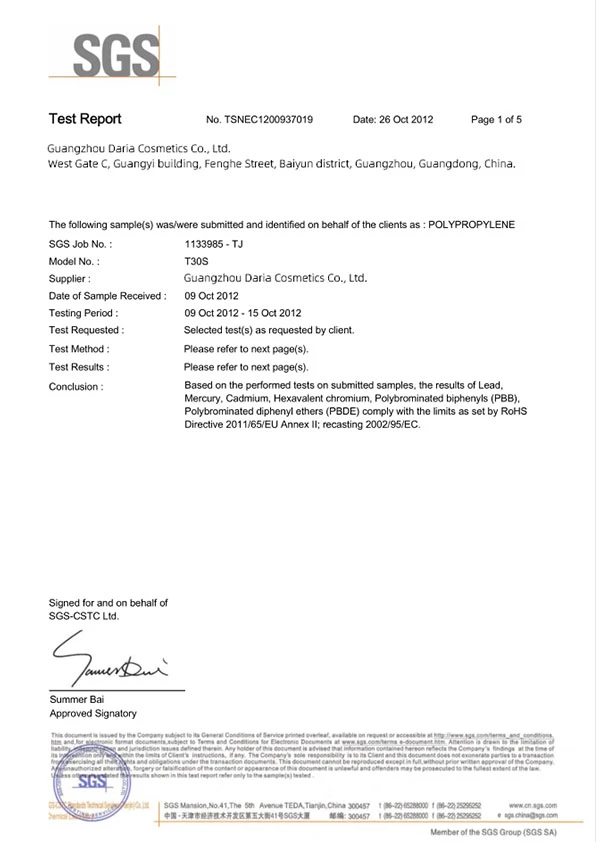

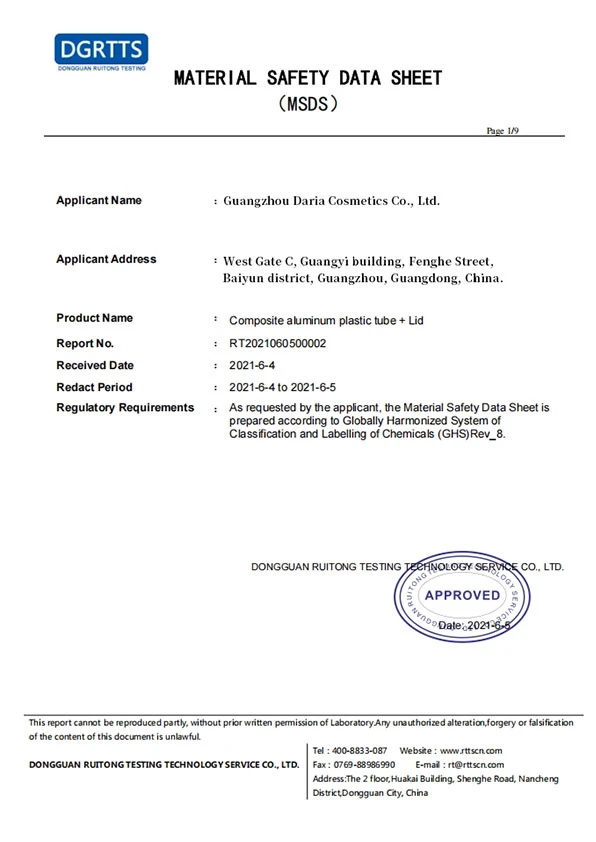

Certification

Certified Commitment to Global Quality Standards

Our ESG Commitment: Sustainable Packaging Solutions for a Responsible Future

Let’s Create a Sustainable Future Together

ESG Commitments: Sustainable Beauty Packaging

At Daria, we believe beauty should never compromise the planet. As a trusted partner for skincare, nail art, and perfume brands, we are committed to advancing sustainable packaging solutions that align with global ESG standards. Our practices prioritize environmental stewardship, ethical sourcing, and innovation to empower your brand’s green transformation.

Environmental Stewardship

30% recycled materials (GRS/FDA-certified) in glass/plastic packaging. Lightweight, recyclable & biodegradable designs minimize waste.

Social Responsibility

Safe workplaces, fair wages, and REACH/FDA-compliant products. Support local recycling.

Ethical Governance

Ethically sourced materials, ISO 27001 data protection. Partner-driven innovation: refillables & bio-plastics.